WHAT IS MICROWAVE STERILIZATION?

A TECHNOLOGY DESIGNED TO REVOLUTIONIZE THE FOOD INDUSTRY

The ready meal market is extremely interesting. Demand, worldwide, has considerably increased with growth prospects linked to changes in eating habits that are moving from the home meal to collective and precooked food services. Current offerings are based on expensive technologies (the frozen food chain) with product quality that sometimes leaves a lot to be desired.

Next Food has set its sights on the food preparation, cooking and preservation sector, taking advantage of the benefits offered by microwave technology, which although widespread on a consumer level, has not been developed at all in its industrial application.

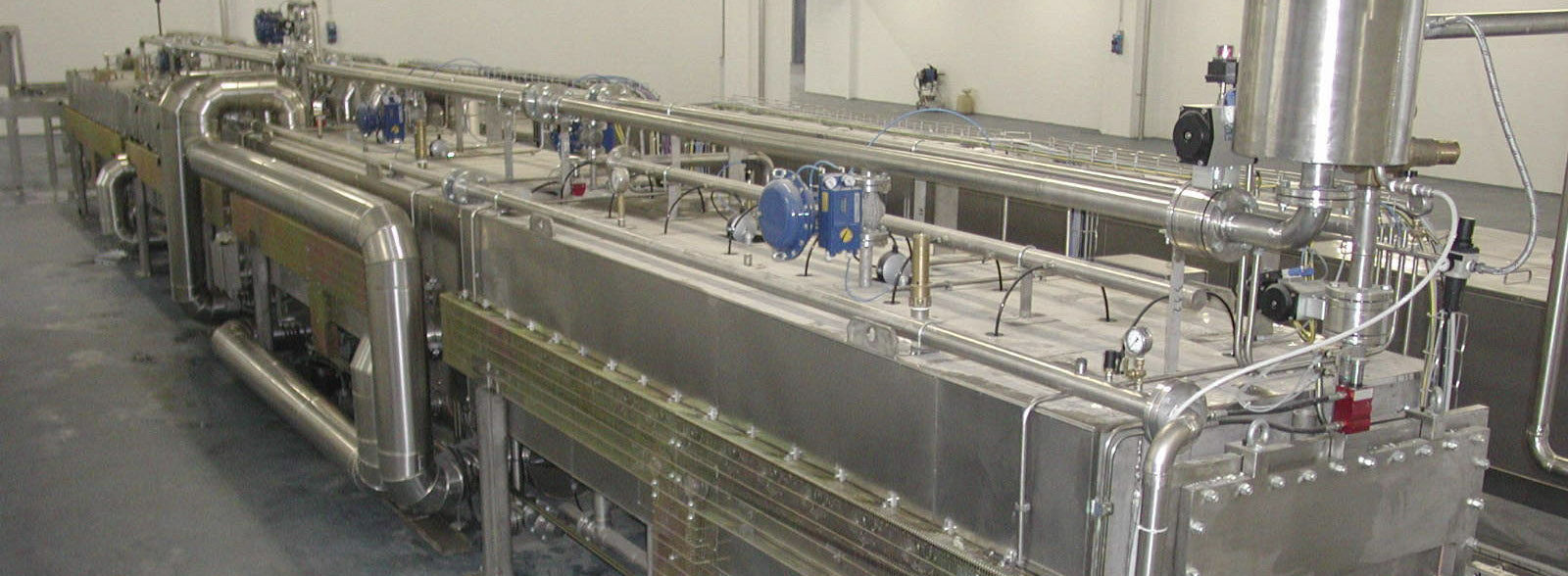

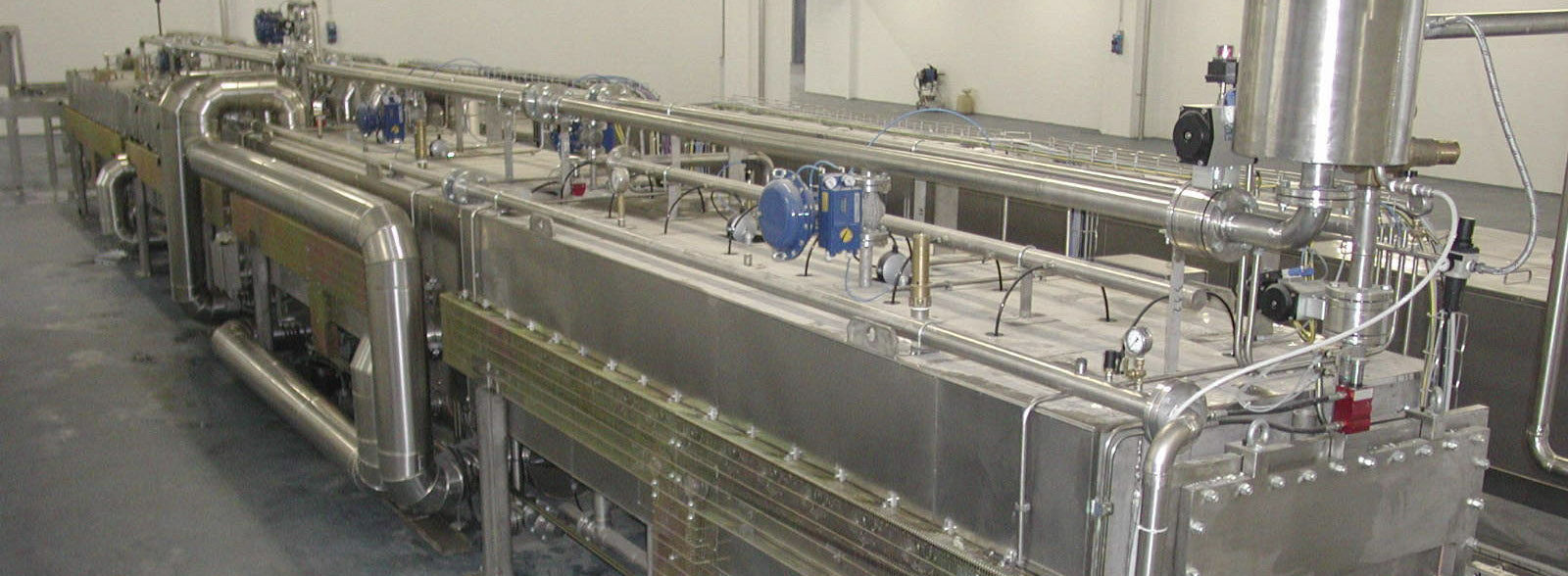

The innovative sterilization system developed by Marco Bertani together with the SMC engineering company is based on the use of microwaves (and only part of the steam), which allow a rapid transmission of heat within the product. In the industry over the last 20 years, research has focused on microwaves as holding the key to revolutionizing the technology of food storage. Excluding minor developments that have not yet led to anything commercially relevant, the main examples in the world, apart from Next Food, are:

A pilot plant built at Washington State University by a pool of researchers coordinated by Professor Tang. The research activities are financed by a consortium that was established in 2001 bringing together some of the most important global food companies (Nestlé, Masterfood, Hormel Food, etc.). Next Food (in its previous incarnation as Gustosì) is mentioned in “related links” of the WSU website www.microwaveheating.wsu.edu. We report below a document outlining the advantages of microwave sterilization illustrated by the Washington State University (*)

What are the advantages of microwave sterilization technology and how it will benefit consumers?

There are a number of advantages of this novel and versatile food processing technology:

- A significant reduction in the thermal processing time while making food safe for consumption is the major advantage of microwave sterilization processing.

- The reduction in processing time results in more fresh-like taste and texture, and improves visual appeal of the food. The reduction of processing time also increases retention of nutrients in the thermally processed foods.

- Instantaneous turn-on and off of the process allows for a more precise process control, better energy usage, and cleaner working environment in food processing facilities.

- The use of post packaging processing could benefit manufactures in reducing spoilage, eliminating refrigeration costs, and provide safe foods for consumers.

- The microwave sterilization/pasteurization technology offers great opportunities for innovative food companies seeking to develop new food products which have not been possible due to limitation of severe heat in conventional retorting.

Can microwave sterilization be used for processing all foods?

Many heat sensitive products made by conventional thermal treatments often result in considerable changes in the quality of the food and make these products unacceptable for consumption. The shorter time and more uniform volumetric heating of microwave processing offers major advantages over conventional steam retorting in producing a wide range of high quality shelf-stable food products: liquid, semi-solid and solid.

At Washington State University, products such as salmon fillets, macaroni and cheese, massed potato and beef in gravy have been processed with proven safety.

(*) fonte sito www.microwaveheating.wsu.edu